Hi,

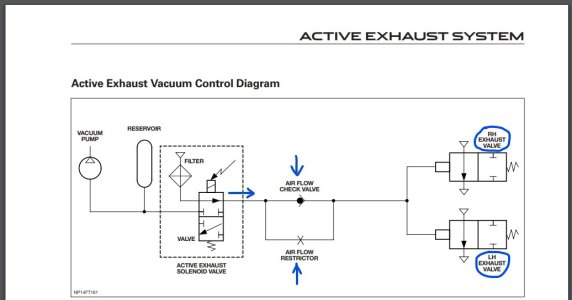

My exhaust valves don’t appear to be working on my 2016 v6s.

The light on the exhaust button comes on when it should.

I can move the valves with my hands fairly easily.

Fuse 43 is in and not blown.

The vacuum lines look like there all

Connected

Is it likely the vacuum pump has gone?

Is there a way of testing the pump, or is there anything else I have missed checking??

Thanks

Simon

My exhaust valves don’t appear to be working on my 2016 v6s.

The light on the exhaust button comes on when it should.

I can move the valves with my hands fairly easily.

Fuse 43 is in and not blown.

The vacuum lines look like there all

Connected

Is it likely the vacuum pump has gone?

Is there a way of testing the pump, or is there anything else I have missed checking??

Thanks

Simon